Understanding Hydraulic Ball Valves: A Complete Guide

Hydraulic ball valves are fundamental components in fluid control systems, renowned for their efficiency, durability, and reliability. This article delves into the intricate world of hydraulic ball valves, highlighting their importance in various applications, their operational principles, and the specific benefits they offer to industries that depend on precise fluid management.

The Basics of Hydraulic Ball Valves

A hydraulic ball valve primarily serves to control the flow of liquids and gases in a system. These valves utilize a hollow, perforated ball to manage flow, allowing for quick shutoff and control. When the ball's hole aligns with the flow direction, the fluid can pass through; when it is perpendicular, the flow is blocked.

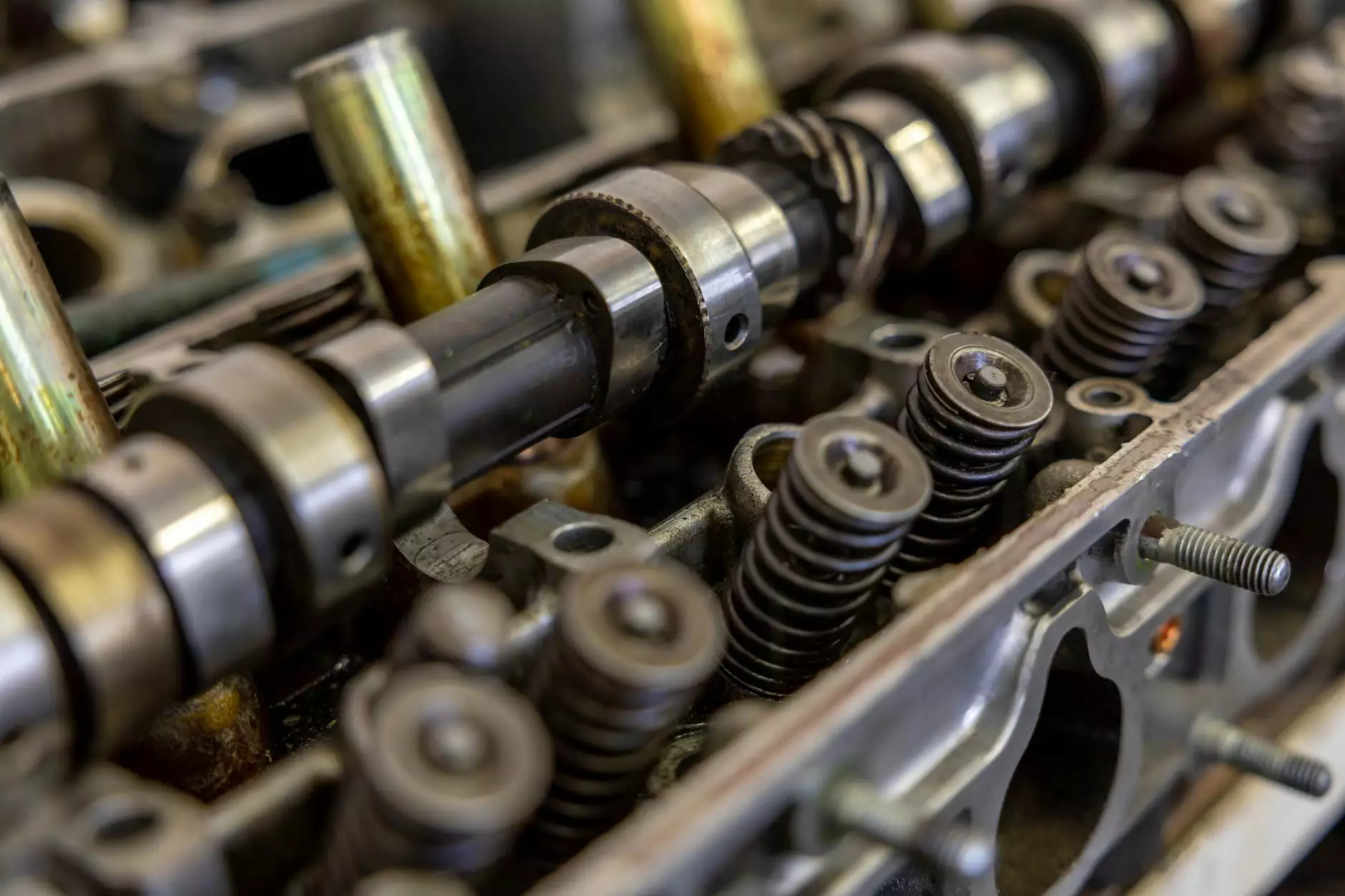

Components of Hydraulic Ball Valves

- Body: The main structure that houses the valve mechanism and is constructed from materials resilient to pressure and corrosion.

- Ball: The core component that regulates flow, made of metal, plastic, or ceramic for durability.

- Stem: Connects the ball to the actuator, translating handle movement into ball rotation.

- Seals: Ensures a leak-tight fit between the body and the ball, enhancing reliability and preventing fluid loss.

Why Choose Hydraulic Ball Valves?

The advantages of hydraulic ball valves stem from their design and operational characteristics. Here are some reasons why they are preferred in many applications:

1. Quick Operation

One of the most distinguished features of hydraulic ball valves is their ability to open and close quickly. This rapid operational capacity makes them ideal for scenarios requiring swift responses to changes in flow conditions.

2. Minimal Flow Resistance

Due to the design of the ball and the straight-through flow path, hydraulic ball valves offer minimal resistance to fluid flow. This characteristic makes them highly efficient, allowing for maximum flow rates without significant pressure drops.

3. High Durability

Constructed from robust materials such as stainless steel and brass, hydraulic ball valves are capable of withstanding harsh environmental conditions, including high pressures and temperatures. Their durability results in a longer service life, reducing the need for frequent replacements.

4. Versatile Applications

These valves are suitable for various applications, including those found in:

- Chemical Processing: Handling aggressive chemicals safely.

- Water and Wastewater Management: Flushing and regulating flow.

- Oil and Gas Industry: Controlling heavy liquid and gas processes under high pressure.

Operational Principles of Hydraulic Ball Valves

Understanding how hydraulic ball valves work can significantly enhance your ability to implement them effectively in your systems. Here’s an overview of their operational principles:

Flow Control Mechanism

The flow control mechanism of a hydraulic ball valve is central to its functionality. When the valve is opened, the ball rotates 90 degrees, aligning with the pipeline's flow direction. When closed, it rotates back to its original position, preventing all flow. This design minimizes turbulence, ensuring smooth fluid passage.

Installation and Maintenance

Proper installation and maintenance of hydraulic ball valves are vital for optimal performance. Here are some best practices:

- Correct Orientation: Ensure the valve is installed in the correct orientation, with the flow direction indicated on the valve body.

- Routine Inspections: Periodically check seals and connections for wear and leakage.

- Lubrication: Apply lubricant to the stem and ball interfaces to facilitate smooth operation.

Applications in Various Industries

Hydraulic ball valves are used extensively across multiple sectors. Here are some examples:

A. Manufacturing

In manufacturing environments, hydraulic ball valves control the flow of various fluids used in production processes. Their reliability ensures the uninterrupted operation of systems that rely on a consistent supply of materials.

B. Automotive

Hydraulic systems in the automotive industry depend on ball valves for effective fluid management, particularly in braking systems and power steering applications.

C. Agriculture

In agricultural settings, hydraulic ball valves regulate water flow in irrigation systems, allowing for controlled distribution of water to crops while conserving resources.

Choosing the Right Hydraulic Ball Valve

Choosing the right hydraulic ball valve involves considering several critical factors:

- Material: Consider the materials used for construction based on the fluids that will be handled.

- Size: Ensure the valve is appropriately sized for your system to maintain flow efficiency.

- Pressure Rating: Check that the valve can handle the required pressure levels without risk of failure.

Conclusion

Hydraulic ball valves play a crucial role in numerous fluid control systems across various industries. Their ability to provide reliable, fast, and efficient flow management makes them indispensable components in modern engineering. As the industry continues to evolve, the importance of utilizing quality hydraulic ball valves cannot be overstated. Investing in high-quality hydraulic ball valves is essential for ensuring the longevity and efficiency of your operations.

For high-quality hydraulic ball valves and other fittings for sale, visit fitsch.cn. Partnering with trusted suppliers ensures that you receive products that meet the highest industry standards, safeguarding your systems and enhancing overall productivity.